Light strip class: how to distinguish the quality of light strips and look at the superficial skills from expert’s Views

On November 27, 2021, rose Lighting invited some companies from whole led strip Participant ,such as circuit boards company , led chips company , SMT processing company , tin wire, wires, adhesives, reels, waterproof processing, and third-party inspection agencies .ect

Let’s discuss how to make a good light strip and how to distinguish the quality of the light strip.

hope below is helpful to yours

From a professional point of view, there are many considerations for the quality of light strips.

From a non-professional point of view, four methods can be distinguished.

1.Professional knowledge of circuit boards.

At present, all our engineering lamp belts are made of 35-bottom copper,

standard width (10mm is the positive 10mm, not 9.3mm), and double-sided laminated products.

In appearance, the color is bright and clean, and the contrast is immediate.

Single-sided boards have a lot of holes in the back,

depending on the thickness of the adhesive, these are e-commerce grade goods which are not good quality.

2.Lamp beads and chip technology

I have suffered a lot. In 2021, there are still people who can make the lamp beads in batches. Suppliers who always say “almost” should stay away.

As the soul of the light belt, lamp beads are very important. You must choose a supplier with a history, a formal factory, a firm, quality pursuit, and consistent measures.

At present, we choose “Jiuyangsheng” and “Opscoled”as our strategic partner, and continue to introduce more good products on the basis of trust.

3.SMT process

The SMT process of the light strip mainly includes solder paste, steel mesh, testing and other specialties, and the degree of mechanization is relatively high.

The SMT process of the light strip mainly includes solder paste, steel mesh, testing and other specialties,

and the degree of mechanization is relatively high.Mainly the difference between lead and lead-free

1. Lead solder alloys have low melting point, low soldering temperature, and less thermal damage to electronic products;

lead solder alloys have small wetting angles, good solderability, and the possibility of “false soldering” in the product solder joints is small;

solder alloys The toughness is good, and the anti-vibration performance of the formed solder joint is better than that of the lead-free solder joint.

2. Lead-free soldering process. According to the current research results, the melting temperature of alternative alloys is higher than that of the existing tin-lead alloys.

For example, from the perspective of the “tin-silver-copper” alloy that is currently more likely to be widely accepted by the industry, the starting melting point is 217°C,

which will greatly reduce the process window in the welding process.

All of our Yaqing light strips adopt lead-free technology, and the global standard is unified, so that Chinese people can enjoy the same quality as foreigners at a lower price. .

there are four reason make Some components moved after put it inside reflow oven

1是钢网开得不精确

建议拿样板实物去开钢网–而不是文件

2锡膏要匹配回流焊的温度

3 传送带的速度要匹配板子的厚度

4 要贴正-贴片机精准度

1 is that the stencil is not opened accurately

It is recommended to use the real sample to open the steel mesh – not the file

2 Solder paste should match the temperature of reflow soldering

3 The speed of the conveyor belt should match the thickness of the board

4 To stick to – placement machine accuracy

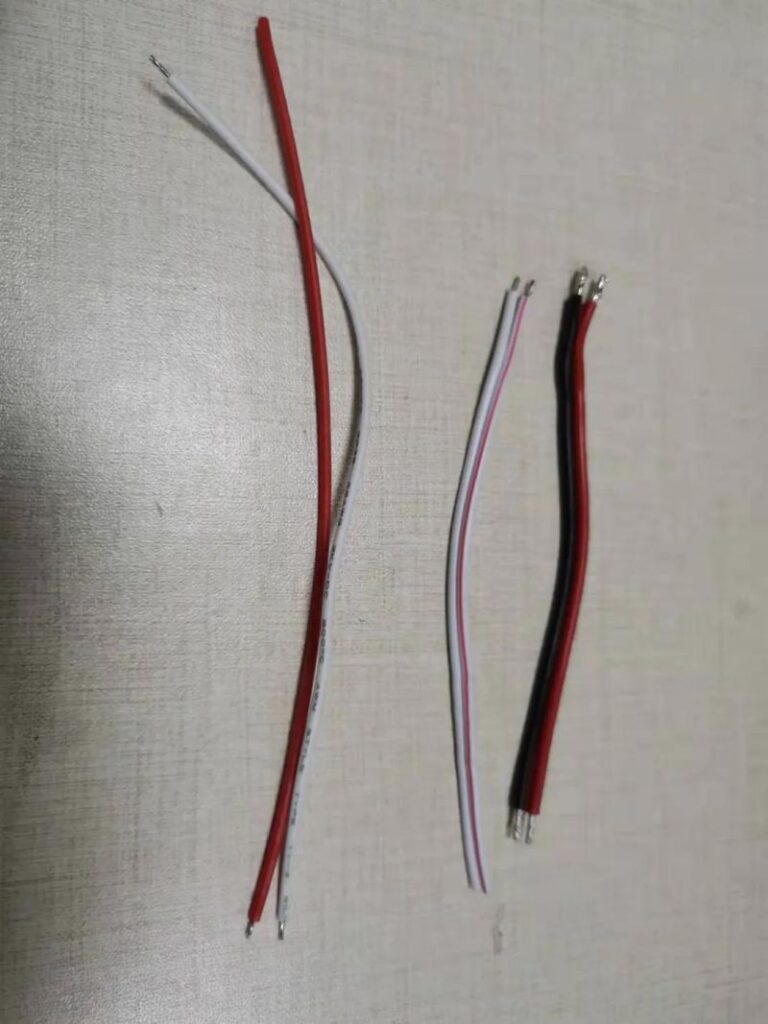

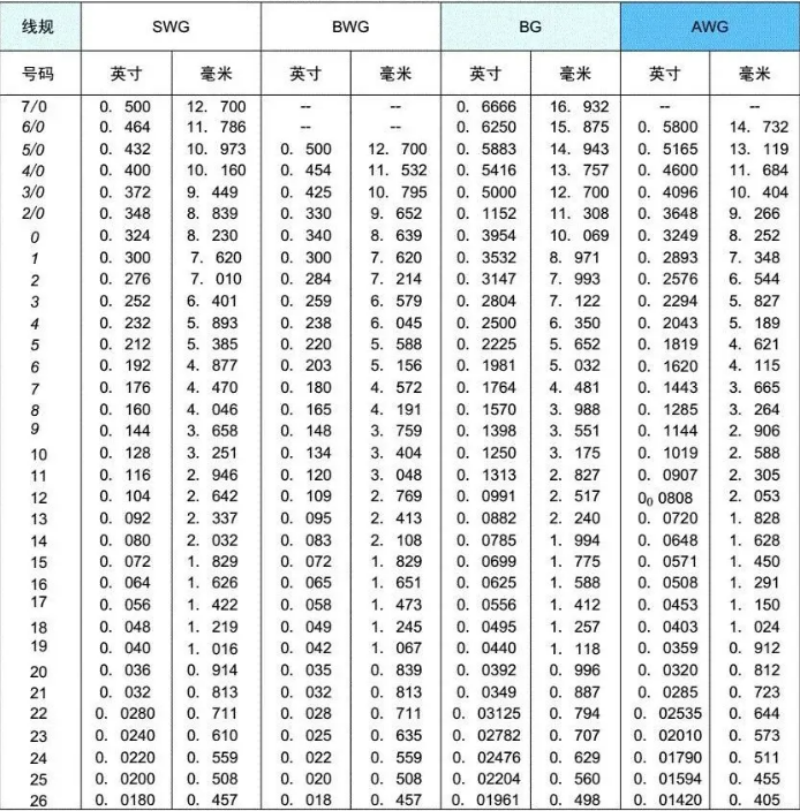

4. Wires.

The knowledge of wire is also a sub-industry, not only materials science, but also electricity safety

If the light strip requires 10A current, and the result is a 6A wire, there must be hidden dangers, and the wire core will heat up and melt.

In another case, the outer skin is not fireproof. If it encounters a short circuit,

it is very flammable and toxic. Hope that this kind of accident will not happen.

We have standard wiring requirements and strictly implement the standards to ensure that customers can use safe and secure products.

5. The glue strip use.

Glue filling is a subdivided process, and there are many manufacturers that specialize in this business.

Currently I know epoxy resin, silica gel, PU (real and fake PU), and other glues.

The performance is mainly yellowing resistance, environmental use and other issues.

A long time ago,an American customer who claimed to be a PhD in chemistry questioned one of our epoxy light strips,

saying that this glue is toxic and will damage male reproductive function.

For this reason, I specifically went to understand the material of this glue, and epoxy resin was gradually replaced. How to tell?

Professionals can tell by touching, pulling, and smelling.

Unprofessional people can only distinguish between yellowing resistance and bending resistance and other details.

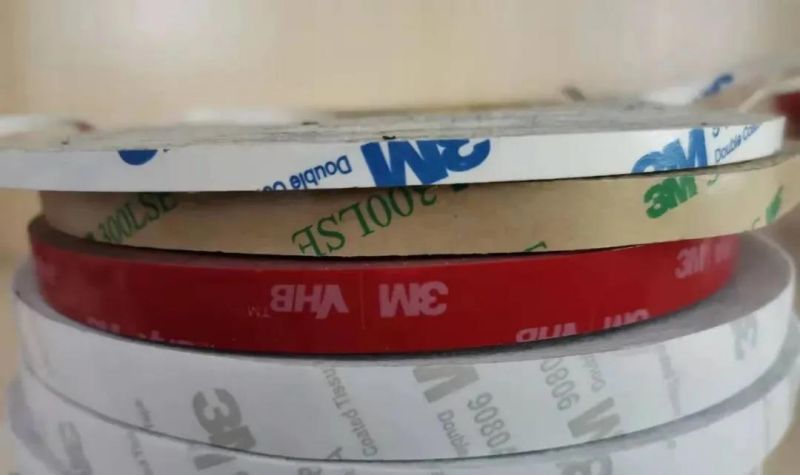

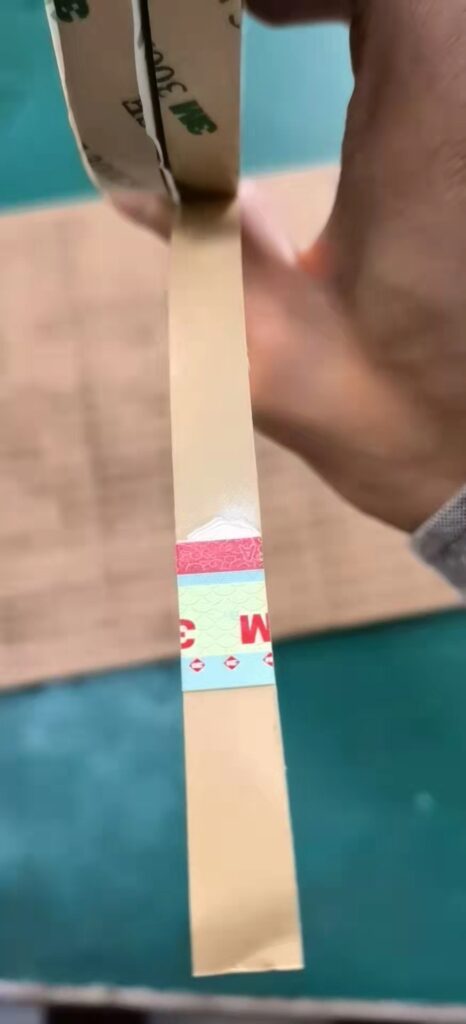

6.Adhesive tape.

In fact, many domestic construction sites use blue adhesive,

but they all say it is not sticky enough. In order to carry out overseas business at the same time,

we have unified the standards and all use 3M genuine adhesives from the United States.

Mainly look at the letter 3M, there are also many imitations in China.

7.CCT.

1)Extrusion process

2)Epoxy filling process

Many designers have very high requirements for CRI, color temperature, color tolerance, and illuminance.

We cooperated with several customers to do this, and they all said that in the future,

all the quality light strips of the engineering model will be ordered by me.

Good products are compared. Now customers are getting richer and richer,

even if they are rich, they will not be able to buy good products.

8.Reel.

There are two types of reel, original material and nozzle material, mainly to look at whether it is brittle, not brittle, and durable.

This is the appearance skill, the same also gives extra marks to the product

9.Brand

We are not a big brand, we can even call it a small workshop. But we continue to learn from the predecessors of the industry,

a little bit to make this product the most professional, worthy of my customers.

Why do I want to mention the brand, because those who cherish their feathers will have determination to make good products and serve customers well.

We have been working hard to make the light strip products better.

At the same time, in terms of after-sales, we have a more far-reaching layout to achieve our risk awareness of one-to-one compensation, and we must do it well.

WHY CHOOSE US ?

1)Using branded lamp beads, high luminous efficiency, low luminous decay, energy-saving and power-saving, durable

2)Using thick PCB board, good electrical conductivity, low voltage drop, fast heat dissipation, good stability and long service life

3)Use lead-free solder paste, PS reel, genuine 3M adhesive, pure aluminum anti-static bag

4)The resistance is placed horizontally, the light strip is not easy to be unsoldered when bent, stable voltage and current, durable and anti-aging

by the way

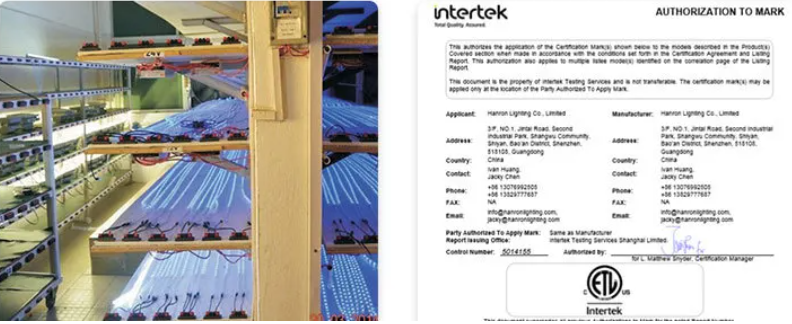

Our Quality Management partner- Shenzhen Back Morning Quality Management Co.,Ltd -as well as the long term cooperation with Osram

we are very pleased to work with the serious company and make real product with real data ,

they are 3Rd party Supplier Quality Management Company for OSRAM and Thorn.ect . .. Osram has long term cooperation with them.

They provide inspection, testing, audit service for other lighting brands ,

they are professional on Suplier Quality Management 1 stop service with service as follow

-Quality Improvements

-NPI

-Quality Inspection

-Lighting Testing

-Factory Audit

With profeesional test machine and experts team, Back morning has won good reputation in led industry and has been the only quality management company of Osram in Southern China !

we are very pleasd to learn a lot from the 3Rd party Supplier Quality Management Company ,know more lighting quality information from our blog as follow please

PS:Rose Lighting is professional led strip manufacturer ,which integrating production, R&D, sales and engineering .