Test the signal transmission quality of hd107s and voltage drop issue

https://www.youtube.com/watch?v=6xEag8E-GSo

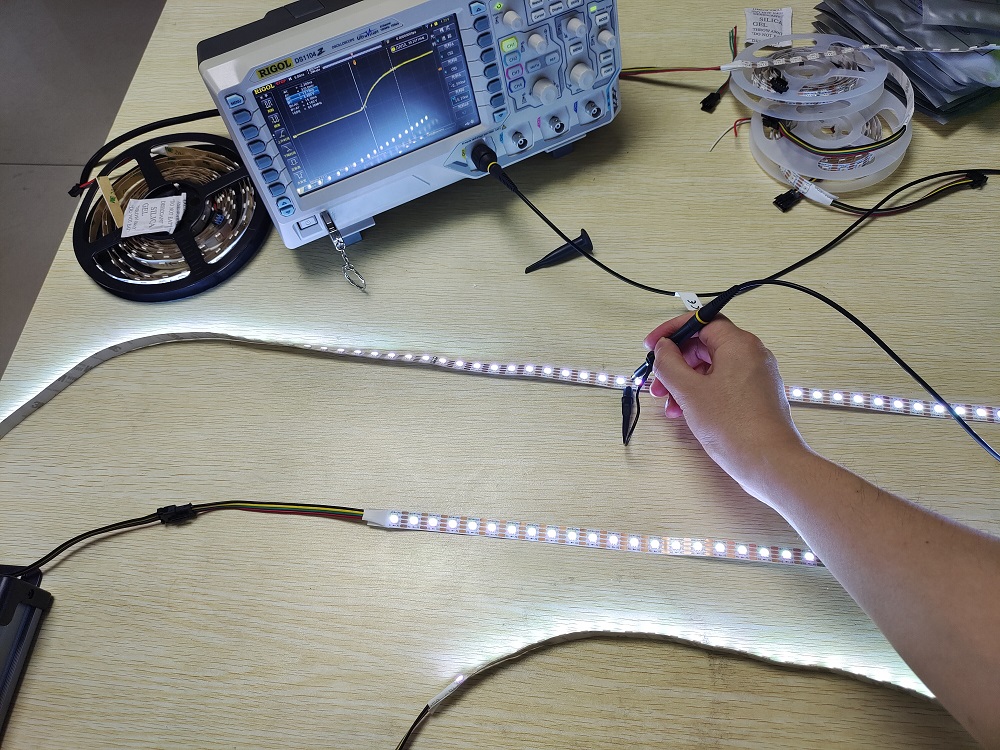

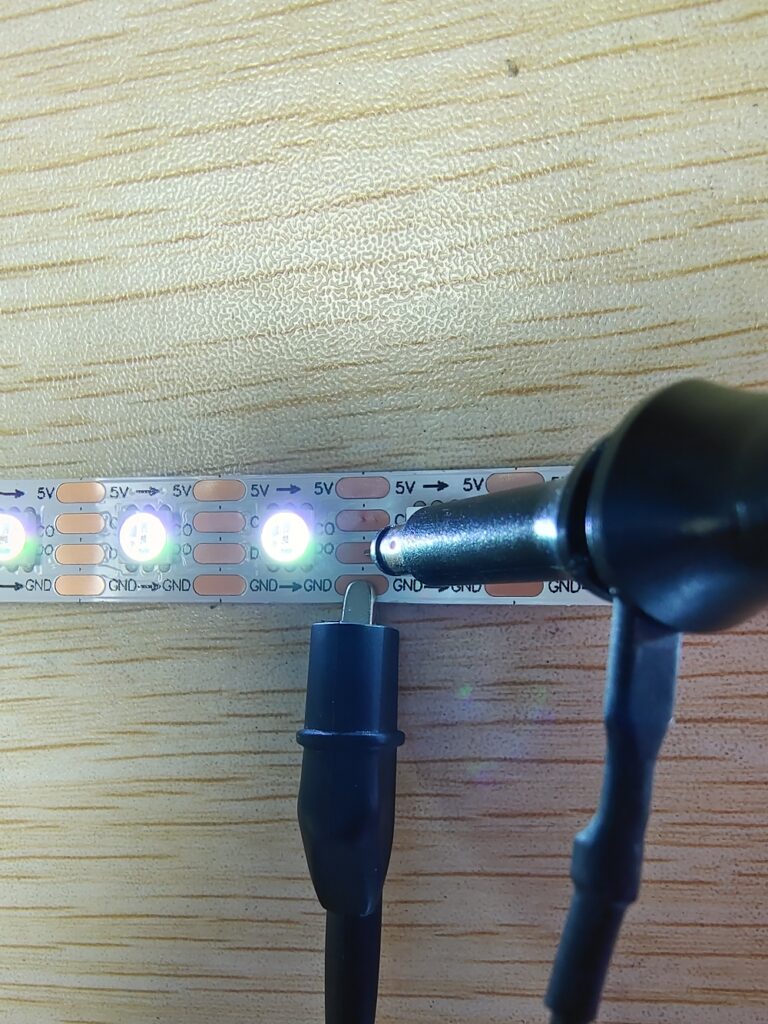

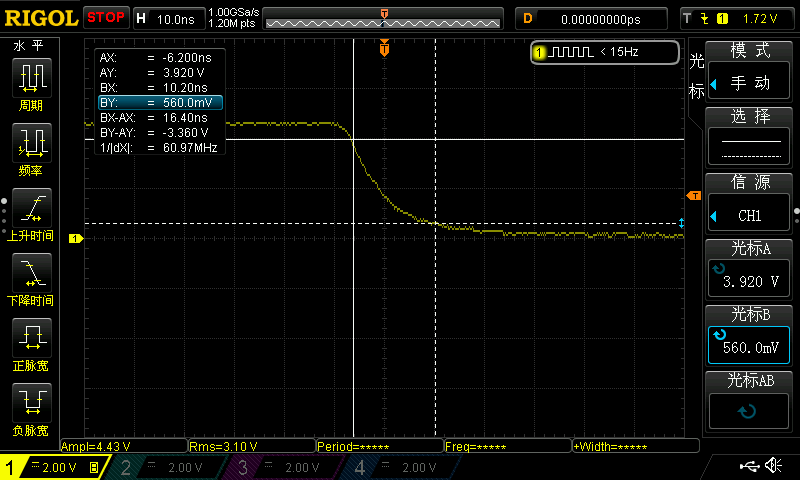

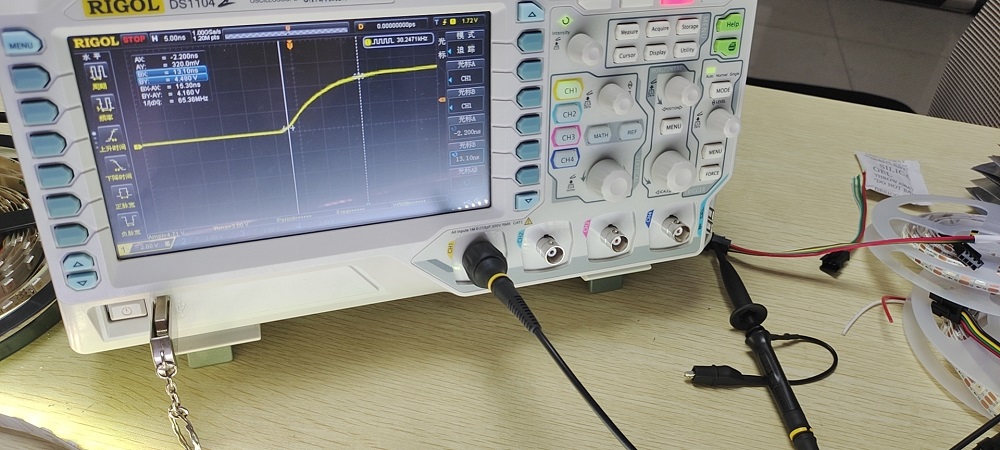

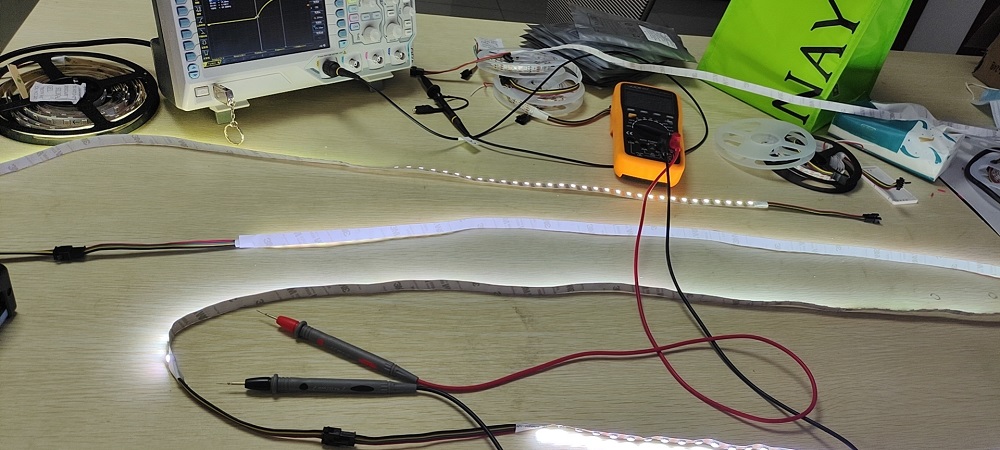

In order to test the signal transmission quality of hd107s, we cascaded a 3M hd107s lamp band,

tested the pulse edge of DAT and CLK signals of hd107s lamp beads in the middle of the lamp band with an oscilloscope.

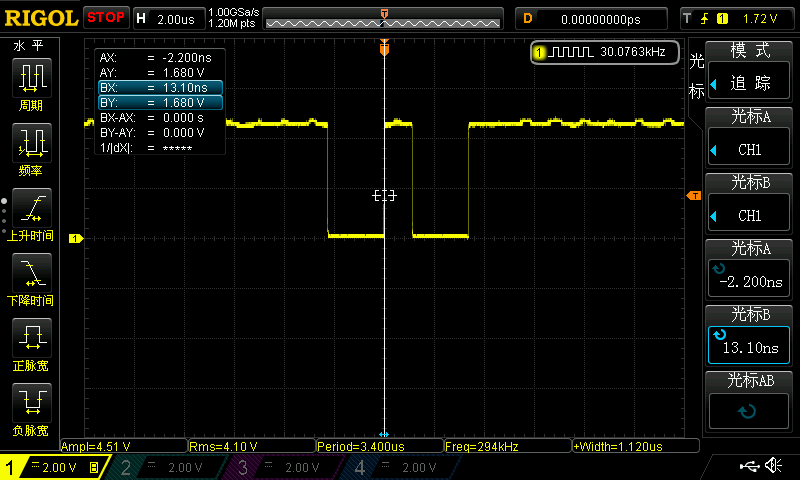

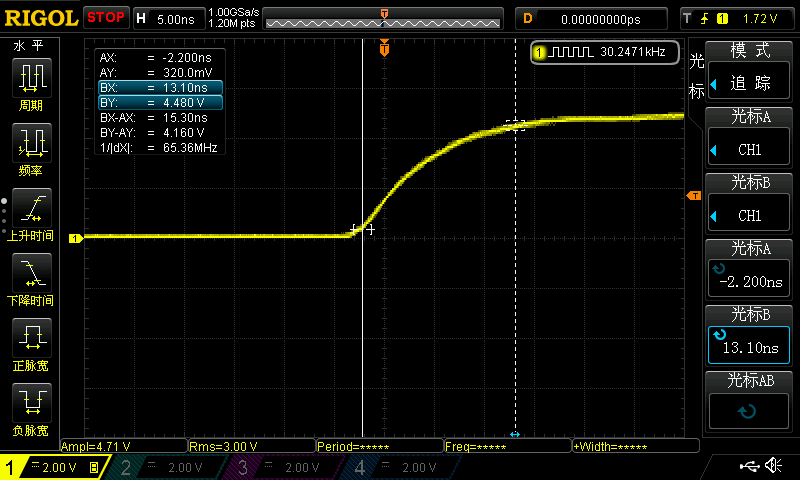

Through the edge duration of these two signals, we can calculate the maximum transmission speed of hd107s.

It can be seen from the test that the duration of the rising edge and falling edge of CO and do signals are basically the same.

The time of the rising edge is about 15.3ns and the time of the falling edge is about 16.4ns.

It can be calculated that the maximum working clock frequency of hd107s lamp band will not exceed 31.5MHz = 1 / (15.3ns + 16.4ns).

Later, we will conduct more specific tests on the transmission time difference of DO and CO signals and the actual maximum working frequency.

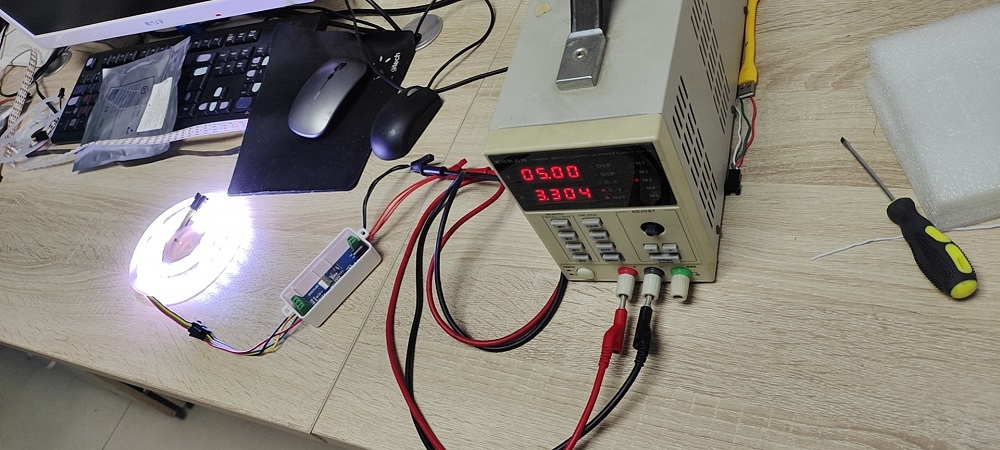

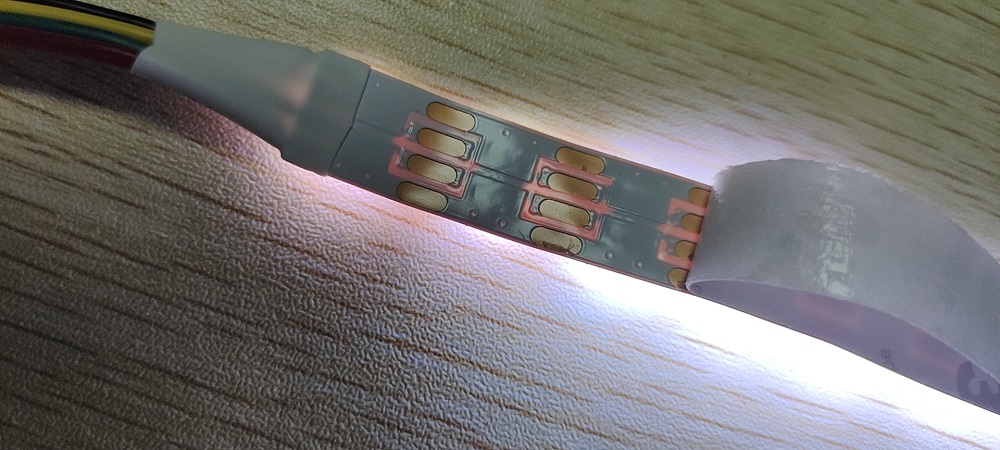

let us make a summary about the test of HD107s led strip ,the pressure drop is large, it is hot and it caused the led lamp dead,

The possible reasons are as follows.

The first is the production process.

Temperature and time in the reflow soldering curve,

solder paste quality, anti-static, electrostatic damage,

especially in autumn and winter, it is recommended to have silver-containing solder paste for good electrical conductivity)

The second is the quality of lamp beads (magic light strips, it is recommended to install external components, more stable, etc.)

The third is the quality of the board (purity thickness density of copper foil)

The fourth is the board design (via holes, copper foil coverage, current circuit design should be large,

in order to ensure the quality of the board, it is recommended to make a board test frame, etc.)